Parts Machinist

Responsibilities

Parts Machinist will be responsible for keeping up with the demands of standard and custom parts.

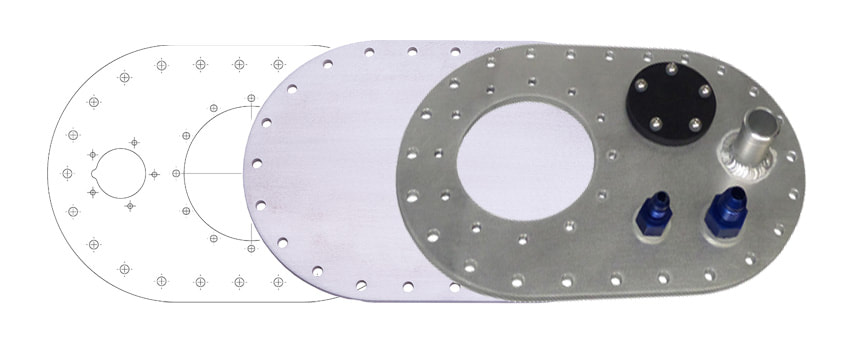

Harmon Racing Cells has their own line of parts and products, and it will be the Parts Machinists' responsibility to do

final assembly of those parts, which could involve additional in house machining and packaging for anodizing.

Although most of our parts are made off site, there are many occasions when custom drilling of plates and other parts

are needed to fulfil an order.

Prior to the customer orders being assembled it will be your responsibility to check off and make sure all parts for the order is

completed, and assembled together for completion of the fuel cell.

Parts Machinist will be responsible for keeping up with the demands of standard and custom parts.

Harmon Racing Cells has their own line of parts and products, and it will be the Parts Machinists' responsibility to do

final assembly of those parts, which could involve additional in house machining and packaging for anodizing.

Although most of our parts are made off site, there are many occasions when custom drilling of plates and other parts

are needed to fulfil an order.

Prior to the customer orders being assembled it will be your responsibility to check off and make sure all parts for the order is

completed, and assembled together for completion of the fuel cell.

Duties

Parts Machinist Duties include but not limited to:

- Keeping on task if not ahead of schedule

- Coordinate production workflow for one or multiple products

- Plan and prioritize operations to ensure maximum performance and minimum delay

- Determine equipment and raw materials needed to cover production demand

- Collect all material and equipment needed to begin the process

- Take precision measurements to ensure perfect fit of components

- Select or modify components according to measurements and specifications

- Align material and put together parts to build more complex units

- Check output to ensure highest quality

- Maintain equipment in a condition that does not compromise safety

- Keep records of production quantities and time

- Report on issues, malfunction or defective parts or machinery

- Collect all material and equipment needed to begin the process

Qualifications

Qualifications for the Parts Machinist are

Experience with shop machinery ie; manual lathe, air tools, hand drill, jig saw, band saw, drill press.

Including an understanding of safe use, and willing to use all safety clothing, eye gear, gloves, face mask.

Proper use and maintenance of all shop tools

Physically healthy, stamina for long hours of standing,

Experience with shop machinery ie; manual lathe, air tools, hand drill, jig saw, band saw, drill press.

Including an understanding of safe use, and willing to use all safety clothing, eye gear, gloves, face mask.

Proper use and maintenance of all shop tools

Physically healthy, stamina for long hours of standing,

- having manual dexterity skills to work with small parts

- ability to lift 50 pounds

- Able to work in uncontrolled environment of 40-100 degrees depending on weather conditions.

- Able to read and write English to deliver information to management and coworkers,

- Able to understand technical documentation and cad drawings.

- Good math and analytical skills for converting and reducing fractions, and decimals.

- Accurately read and measure with a tape measure, drywall square, ruler and angle finder.

- Understanding for the use of quality control and follow the guidelines.

- Detail-oriented, organized and problem solver.

- Motivated to achieve precision-built products in a safe and timely manner.

- Team player, but independent worker.

- Coordinate with other employees as a team and work independently, efficiently

- in a timely manner and stay on task.

*Please send resume to, jim@harmonracingcells.com